A better, stronger more sturdy hive with little-to-no maintenance is needed so that a beekeeper can focus on the bees and honey production. Eco Bee Box has parts to repair, enhance, replace, make them windows to the world and they are an evolutionary leap forward in hive technology. Our pillar is advancement Thru Education, Practice and Research.

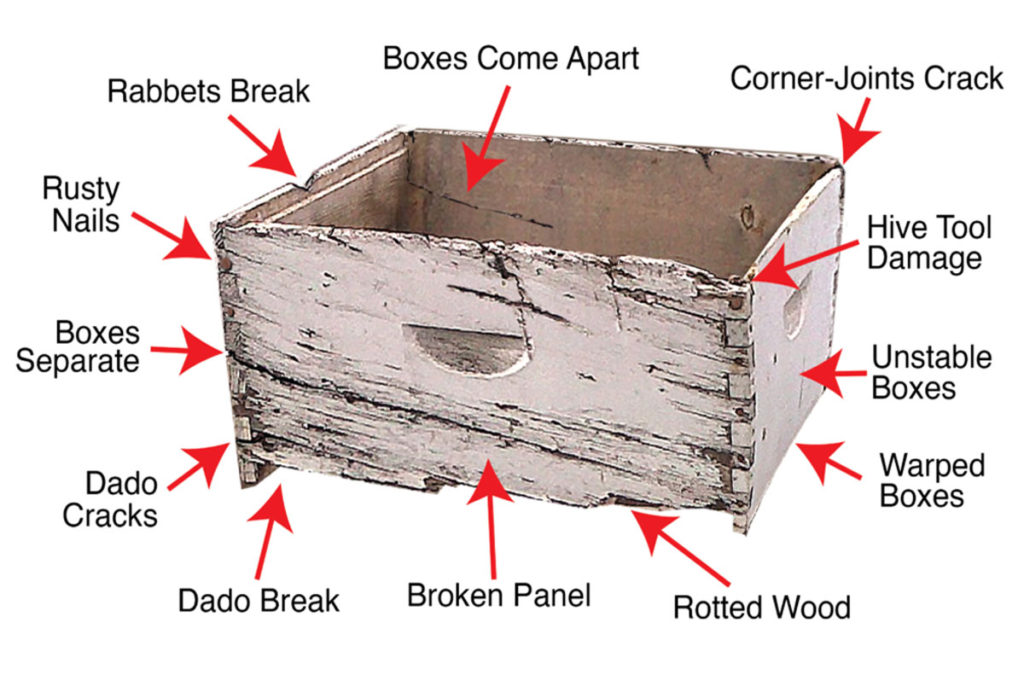

Problem #1: Hive boxes are prone to failure

A frustrating feature of the current finger-joint box is that each manufacturer has different specifications. It is difficult and impractical to take used panels from one old box and use them to repair another broken box. Additionally, shrinkage of lumber after the panels are assembled - can cause the assembler of the box severe frustration when box joints don’t fit. Panels are constantly acclimating to moisture and heat conditions. Panels can warp or cup, they can split, and shrink prior to and after assembly, causing overwhelming stress. Once assembled, lumber continues change, which causes stress cracks and obvious break down.

Solution: ECO BEE BOX's CORNER BRACKET

Our bracket solves these problems and allows a beekeeper to spend less time and money handling the boxes and more time caring for the bees. Currently two styles are available: one for new construction and the other for repairs on traditional corners (called repair caps).

Problem #2: Paint conflicts with interior & exterior

Paint can cause harm. Lead paints were widely used over the last century, but are now mostly abandoned. Latex paints are laced with fungicides. Paints all have a degree of toxins. The older the box, the likely-hood more toxins will exist. Bee hive supers are exposed to exterior elements and high humidity within. Paints fail, requiring the beekeeper to sand and repaint. Respirators are needed as a safety measure. Paint can be costly and difficult to apply once bees occupy the hive.

Solution: ECO BEE BOX's BECKS BEES WAX

Problem #3: Sustainability

Currently when problems occur with the woodenware, too often the box is discarded. Broken rabbets are a weak feature of a Langstroth beehive. Beekeepers accidently pry frames loose, or mismanage them, and the 3/8" pine rabbet breaks. Creating a durable replacement is elusive once broken.

Solution: ECO BEE BOX's ALUMINUM REPLACEMENT RABBETS

Problem #4: Inability to recover from hive failure

Sadly most beekeepers are unaware of how to raise a queen bee. Honeybees have existed for about 95 million years, and have systems in place to correct queen issues when they occur. If a colony goes without a queen for too long, laying workers can take over causing much grief and potentially total failure. Accidently injuring your queen, or killing queen cells can end your beekeeping season.

Solution: ECO BEE BOX's MINI URBAN BEEHIVE

Problem #5: Disease with current practices

Honeybees naturally live in trees. They build until the space is full or until a threat occurs, and the either abscond or swarm. A natural defense in the bee's makeup is to divide or move. The Langstroth system consists of 2 brood boxes, with honey supers on top. The practise is the first 2 boxes are for the bees to overwinter, honey supers come off and supply the beekeeper with extractable honey. In fall beekeepers remove the honey supers and force the bees down into the oldest most infected comb in the hive. The practise of letting comb get dark, as it is "too costly" for the bees to reproduce is silly. They have a need to produce fat (beeswax) and want to be on newer comb, it is clean. Regularly bees are disinfecting their hive with propolis, including polishing cells until they are black.

Solution: ECO BEE BOX's COMB BOX / BROOD BOX

Problem #6: Equipment exists that is not compatible

Langstroth hives, Top-Bar, Warren, WBC, and on, are all different systems that are not compatible with each other. Frames from one system, does not harmonize with the others.

Solution: ECO BEE BOX's MINI FRAMES